RGB line Vrumona (Pepsi, 7Up, Sourcy)

As Project Manager overseeing the replacement of a 30-year-old bottling line with state-of-the-art equipment. Scope was bottling equipment, civil renovation and expansion of the building, utilities(steam,air,water), electrical systems, automation, and electrical.

Capex 10-20 million euro.

- Coordination of work between three equipment suppliers Krones, KHS and Vision-Tec plus four contractors for civil work, piping, electrical, insulation work.

- Leading multidisciplinairy team of engineers, buyers, contactors, safety supervisor,

- commissioning and start-up, the team stayed responsible until 6 monts after for start-up. Line performance was monitored and improvement actions taken.

Renovation Inbound Warehouse FrieslandCampina, project is expected to finish May 2026

Leading renovation of 7.000m2 warehouse of a dairy factory. Floors, walls, LED lighting. Challange is operation must continue.

made specifications with civil engineer and the team based on audit reports.

tendered the scope of work with procurement team

evaluation of quotes of various contractors

- cost control

- construction management

Waste water treatment plant Heineken Algeria and Coca Cola

With Global Water (GWE) and local contractors and local construction team i built an anaerobic waste water plant to clean industrial waste water and produce biogas. The biogas is used in water boiler.

Civil works was executed by local contractor under supervision of Dutch Engineering firm Tebodin. Equipment was supplied by European contractors

Leading a multidisciplinary team of engineers, buyers, contractors and supervisors.

Reporting to steering team with joint venture Coca Cola and Heineken, and their global organizations.

Delrin Netherlands, Former Dupont

Goal of this project was to collect waste air from plastic production equipment that contains a few ppm of formaldehyde. This air was feed into an existing waste incinerator with modified burners and blowers. The waste incinerator produces steam.

Under my lead:

- Basic engineering

- Tendering, cost estimation, gate approval

- Detail engineering

- Procurement

- Construction

- Commissioning and start-up

Nutricia / Danone Medical Nutricion

Nutricia Danone produces medical nutrition for sick or recovering people and children. This nutrition is available in 125ml, 500ml, and tube-based packaging. I have worked on new UHT and Dissolving line D4 and D5 in almost complete new building. Medium Care Zoning.

- Creation Building design, with integration process design

- Managing external engineering company, progress,cost, planning

- Permitting

- Construction management

Europort Tank Terminal

On client side i was project manager for expansion of Europort terminal with two tanks of 55.000 m3 with 24-30″ underground piping and fire fighting systems. 250.000 manhours without LTI (lost time incident). CAPEX: €30 million investment

- Basic with Bilfinger Tebodin

- Detail Engineering and Construction by Engie Fabricom

- Pipelines by A.HAK

Danang Brewery Heineken

As Project Manager leading international team with contractors from Europe and Asia.

CAPEX: €50 million investment.

Scope was expansion of the Danang brewery, doubling the capacity

- Construction of a Krones brewhouse equipped with a mash filter.

- Construction of a CO₂ recovery plant.

- Addition of new fermentation cellar.

- Installation new cooling plant

- Expansion electrical system

Leading a multidisciplinary team of 15 engineers, buyers, and supervisors.

Engaged Royal Haskoning as external EPCm civil engineering consultant.

Managed local site construction and safety teams.

Fire Fighting System – Delrin Netherlands, Former Dupont

Replacement of deluge sprinkler system by foam based sprinklers in petrochemical factory.

- Basic Engineering

- Selection of technology

- Uitgangspuntendocument Brandbeveiligingssysteem (UPD) together with consultant

- Installation and commissioning

Leading a multidisciplinary team of engineers, buyers, contractors and supervisors.

Reporting to steering team in NL and USA.

Extension Brewery Heineken Gisenyi Rwanda

Gisenyi, is the second largest city in Rwanda. Heineken has a brewery at the lake Kivu and close to the border DRC. Due to high demand we expanded the brewery.

- Brewhouse expansion with mashfilter

- Fermentation tanks

- Replacement of process automation

- Installation new RGB bottline line

- Installation waste water treatment plant

- Emergency Back up generators

As project manager i was responsible for coordination between European equipment suppliers, local and regional contractors and Asian and European suppliers. Part of scope was started by fellow project manager.

TAQA Netherlands

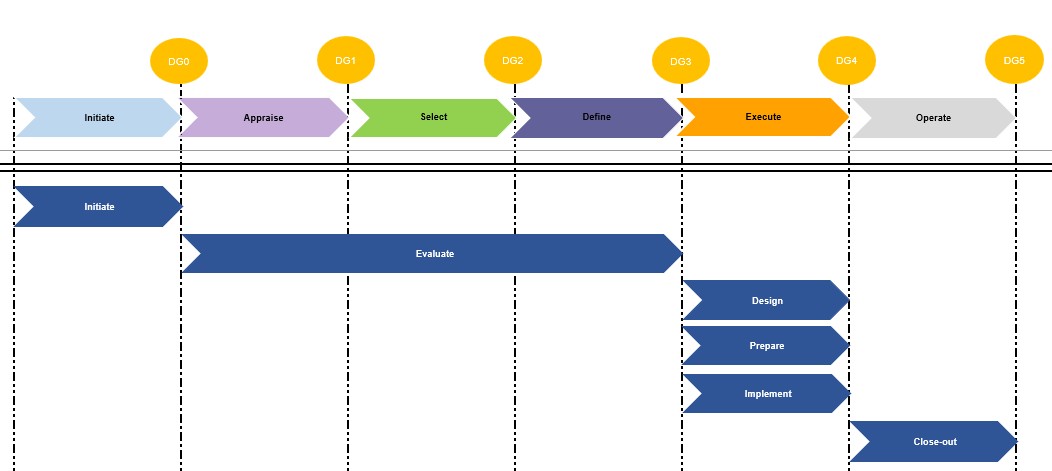

I supported TAQA NL to redesign their project management procedures. In close cooperation with TAQA Project Team leader, I re-introduced the stage gated project process to ensure that stakeholders approve the project objective, the cost and planning before execution starts. We organized workshops and developed tools to train the project managers and engineers

Heineken Myanmar Brewery

As Project Manager overseeing a €15 million brewery expansion to double production capacity. Successfully managed over 80,000 manhours without any Lost Time Incidents (LTI).

- Installation of nano beer filtration system.

- Increased brewhouse throughput (more brews/day).

- Expanded fermentation cellar and tanks

- Construction of a anaerobic wastewater treatment plant. Both civil and equipment

- Piling works for a new packaging hall.

- Emergency Back up generators

Leading a multidisciplinary team of 15 engineers, buyers, and supervisors.

Engaged BECA as external EPCm civil engineering consultant.

Managed local site construction and safety teams.

Apple cider production – Sedibeng South Africa

Project Manager of two phased project to produce Apple Cider. From principal design until start-up.

Due to strong deadlines we executed project in fast track with parallel design and construction.

Phase 1: fast production of Cider with pre-fermented base.

Phase 2: in-house cider fermentation and filtration.

CAPEX value approx. 15 mio euro.

Due to time constraint we opted for single source suppliers, beforehand clearly communicated pro/con of this approach.

DSM Ferminich Delft

DSM Ferminich Delft is producer of high-quality API for antibiotics.

As lead mechanical engineer I participated in a conceptual design for a greenfield factory in China.

- Preparation of Basis of Design, equipment lay-out, requisitions / datasheets for 45 package units

- Evaluation of new available technology / equipment suitable

- Field visit for site selection in China

- Cost estimation +/- 30% (CAPEX 100 mio)

Northern Petroleum Nederland

Northern Petroleum took over 6 gas fields from NAM.

As project lead at Tebodin i lead a multidisciplinairy team

- Mechanical, electrical, automation design

- Procurement

- Package unit design

- Site construction supervision

- Pressure Equipment Directive

Replacement Human Machine Interface Control Room, Dupont Dordrecht

Objective of this project was to replace outdated servers and screens in the central control room. The software is ABB 800xA. The difficulties were to replace software that controls a chemical plant running 24/7 and the change management for the operators.